Roller shutters

Blinds

Curtains

Mosquito nets

Awnings, canopies

Terrace awnings

Garage doors

grids

Intelligent control

Home page / Terms and conditions

Terms and conditions

Regarding the warranty

DEXLINE guarantees and confirms the conformity of the sold goods with the standards and technical conditions valid in the Republic of Estonia, as well as with the requirements of the contract of sale of goods.

In its activity DEXLINE is guided by the legal acts in force in the Republic of Estonia, without deviating from the imperative norms. Free warranty service in case of defects of the product(s) due to the manufacturer's fault (no mechanical damage caused by use) is provided: for individuals - for 24 months, for legal entities - for 12 months.

The warranty is provided upon presentation of proof of purchase.

The warranty is void if the goods are used for other than their intended purpose and/or in violation of the operating instructions, or if the instructions in the operating instructions are not followed or are not properly followed.

DEXLINE may mark its products with a trademark (sticker), it is not recommended to tear off/remove it from the product, otherwise all risks related to the removal of the trademark are assumed by the Buyer.

Recommendations for cleaning roller shutter fabrics

Cleaning of roller shutter fabrics

Regarding the return of products

DEXLINE uses the most advanced technologies in its business, which allows us to offer consumers only high quality products. Please note that products and measured goods of proper quality, which have been specially prepared, cut, cut, etc. at the request of the consumer, cannot be replaced or returned

In case of non-compliance of the delivered goods with the quality requirements, or if the Buyer is dissatisfied with their shape, size, color, model, if the goods were not delivered according to the Buyer's individual order and are not goods that cannot be replaced (returned) according to the requirements of legal acts, the Buyer shall apply to DEXLINE.

Goods are not accepted for return in case of their use and (or) their damage and (or) loss of trade dress (changes in the appearance of the packaging necessary for inspection of the goods are not considered changes in the appearance of the goods). In case of damage to the goods or loss of their marketability due to the Buyer's actions or inaction, the Buyer shall compensate the Seller for the losses incurred by the Seller.

DEXLINE does not take responsibility for measurements provided by customers personally.

PRODUCT PRICING

The exact price of the products is set according to the customer's order after individual measurements. The minimum price rule applies for ordered products with an area of less than 1 square meter (one square meter) - this means that if the total area of the ordered product is less than 1 square meter (one square meter), the customer is obliged to pay the full price of the product with an area of 1 square meter (one square meter).

Regarding the delivery of goods

Ordered goods can be received in all DEXLINE showrooms.

DEXLINE provides a wide range of services in order to maximize customer satisfaction. Among other things, on the basis of a separate agreement with the customer it is possible to provide home delivery services throughout Estonia, both with and without installation service. The price of delivery is calculated individually depending on the customer's place of residence.

The Buyer, who has chosen the delivery service during the order placement process, is obliged to indicate the exact delivery address of the goods. The Buyer is fully responsible for the accuracy of the data provided by the Buyer. In case the Buyer provides incorrect data, the Seller is not responsible for the consequences caused by this.

By signing an invoice or other document of acceptance of postal delivery, you confirm receipt of new goods without mechanical or transportation damage. It is therefore advisable to inspect the packaging for mechanical or other suspicious damage upon receipt of the goods.

Features of the product considered to be its natural properties

The shades, patterns and other similar parameters of the products depicted in the catalogs and/or on the website may not correspond to the shades, patterns and other similar parameters of the real products, and such discrepancy shall not be considered a product defect.

Minor fading.

Different degrees of fading in direct sunlight and shade areas of the product.

Fabrics (roller blinds, vertical blinds) are produced in batches. The shades of fabrics from different batches may differ slightly, and these differences may be more or less pronounced for different types of fabrics. Consequently, the shade of the fabric used for the product may differ from the shade of the fabric shown in the catalog, and the shades of fabrics ordered at different times may also differ from each other (because the fabrics are from different batches). In order to ensure identical fabric shades for several products, it is necessary to order these products at the same time and to specify mounting of these products next to each other. In this case, fabric from the same batch is used to make the products. In case of ordering products at different times, or ordering them at the same time, but without specifying the installation of the products next to each other, the batches of fabric and, accordingly, its shades may differ, which is a normal property of fabric.

Incomplete straightening of the roller fabric after it has been stored in a partially unwrapped state (mechanical memory).

No absolute coincidence of the geometry and symmetry of the pattern with the edges of the product.

Minor stretching, waviness of the fabric due to stress experienced during use (tension, heat, UV radiation, humidity, etc.).

Difference of shades of metal and plastic parts coated with the same paint (insignificant - when "RAL" matches, significant - when "RAL" does not match).

Minor differences in shade and texture of lamellae, bottom profiles, finish of top profiles, control canes.

Minor mechanical defects in wooden components of wooden blinds, invisible from a distance of 1 meter.

Painting over minor mechanical defects of wooden shutters with paint of a coordinated color.

Paint the cut edges of the wooden elements of the wooden shutters with paint of a coordinated color.

The porosity of the cut sections of wooden elements of wooden blinds (open internal structure is visible).

Natural mechanical wear of moving, friction-prone components due to operation.

Roller shutters

Quality Indicators. Product properties

The dimensions of the products can vary within +/-2 mm.

Blackout roller blinds (Black Out fabric, guides, cassette) provide strong blackout of the room, but do not guarantee absolute darkness. Light penetration is possible along the edges of the cassette, through the guides, from the bottom of the lower profile, which, however, is inadmissible through the "Black Out" fabric itself.

The roller shutter is installed horizontally regardless of the geometry of the installation environment. If there are uneven horizontal or vertical surfaces in the place of installation (improperly equipped niche, crooked lintel, crookedly installed window, window sill, etc.), the roller shutter geometry will not coincide with the geometry of the planes located in the place of installation.

The rollette fabric may stretch slightly when exposed to sunlight or other heat source (heating by radiator, blowing hot air). Stretching is manifested as a small wave on the fabric, a "smile". Once the temperature returns to normal, stretching usually disappears.

The roller fabric should be untwisted, leaving at least one and a half turns on the tube. Failure to do so may result in damage to the fabric, which is not covered by the warranty. The end position limiters of the chain prevent the fabric from unwinding completely.

When materials with geometric patterns (stripes, squares, waves, etc.) are used in products, the geometry of the pattern may not coincide with the geometry of the product, i.e. the geometric figures may not coincide with the bottom, top or side edges of the product, which is not considered a defect.

Do not touch the fabric, rub its edges or move the bottom profile. The roller shutter can only be operated by means of a motor or chain.

The light penetration of a roller shutter fabric (except for Black Out) is expressed as a percentage and means the average transmission capacity. In day-night fabrics, this transmittance is due to holes visible to the eye, which is a normal property of the fabric. The number and location of these openings is not standardized.

Mosquito nets

Quality Indicators. Product properties

The dimensions of the products can vary within +/-2 mm.

The shade of the mosquito net/its components may vary slightly from the sample shown.

The shades of different products may differ (for example, the shade of a mesh frame from a roller shutter mosquito net, from a mesh door, and the shade of a rectangular shaped mesh frame from a different shaped mesh frame).

The shades of painted aluminum profiles and plastic parts may vary.

Painted aluminum parts are considered to be of good quality if there are no flecks larger than 1 mm, if the distance between small flecks is greater than 10 mm, and their average number does not exceed 1 unit/dm2. Paint drips are not allowed, the presence of small single scratches on the surface of the paint is allowed. Any defects should not be visible to the naked eye from a distance of 3 meters at an angle of 60 degrees.

The net (the net itself) must not be touched, squeezed, pushed or pulled, as this may cause damage to it or cause it to come loose from the metal structure. The mosquito nets (door, roller shutter, pleated) can be operated by moving them using the holders, handles or cords designed for this purpose, without touching the net directly.

The nets keep insects out on both sides. So if insects have already entered the room through another opening that is not protected by the net, they will not be able to get back out through the net. Such insects try to escape at the point of air circulation, i.e. through the mesh, so they can often be found on the inside of the mesh.

If the mosquito net is not installed correctly (gaps between the aluminum profile and the window/door frame), insects can enter the room.

Mosquito nets do not prevent insects from entering rooms through other structural window/door openings not protected by the net (e.g. condensation holes in window profiles at the bottom of windows/doors).

Anti-allergenic meshes are thicker than ordinary meshes, are made of a different material, therefore have a different color (usually black or gray), are less transparent, and impede air circulation.

Horizontal wooden blinds

Quality Indicators. Product properties

The dimensions of the products can vary within +/-2 mm.

Wood irregularities that are not visible from a distance of 1 meter are not considered defects.

Minor irregularities of wood visible from a distance of 1 m are allowed if they are: a) "zigzag joints" of wood visible only due to the difference in wood structure and color (the number is not limited), b) small joints visible at the edge of the lamella or top/bottom profile, c) thinning of the paint layer, changes in paint color, minor fading up to 2 mm in diameter.

DEXLINE marks wooden blinds, as well as its other products, with a trademark (sticker), it is not recommended to tear off/remove it, otherwise all risks related to the removal of the trademark are assumed by the Buyer. The blinds are designed to be fixed in a free position, in which the wooden blades do not come into contact with other surfaces (wall, window frame, curtains, etc.). When a product comes into contact with other surfaces, and especially when there is friction (e.g., touching frequently with hands, moving the product in a draft), color diffusion can occur on surfaces exposed to friction - darker colored surfaces can stain lighter colored surfaces. For example, if the walls are white and the product is black, the product will paint the wall, and if the walls are dark and the product is light - the wall paint will paint the product.Motorized blinds: motors are not designed for continuous movement of blinds - their one-time operation (raising/dropping of blinds, turning of blades) should last 3-5 minutes. If the motor is operated continuously for longer than this, its thermal protection is activated and the motor switches off. After switching off, the motor cools down for about 15 minutes (if not running), and only then the operating mode is restarted. The above time intervals depend on the size of the louvers and the ambient temperature.

Permissible lamella irregularities: twists - up to 2 mm/m; horizontal curvature - up to 2 mm/m, longitudinal bending for louvre area L ≤ 1.5 - up to 3 mm, for 1.5 < L 2.5 - up to 6.35 mm; transverse bending is not permitted. These restrictions apply to new louvers.

Natural wood lamellas can change shape beyond the above limits when exposed to moisture and temperature fluctuations.

Horizontal aluminum blinds

Quality Indicators. Product properties

The dimensions of the products can vary within +/-2 mm.

The shades of the components of the blinds may vary slightly from those of the samples shown.

The shades of different parts of the product may differ slightly (e.g. lamellae, top and bottom profiles, cords, etc.).

Painted aluminum parts are considered to be of good quality if there are no flecks larger than 1 mm, if the distance between small flecks is greater than 10 mm, and their average number does not exceed 1 unit/dm2. Paint drips are not allowed, the presence of small single scratches on the surface of the paint is allowed. Any defects should not be visible to the naked eye from a distance of 3 meters at an angle of 60 degrees.

The louver blades must not be touched, squeezed, pushed or pulled, as this may cause damage to the louver blades themselves or their supporting structure. The blinds are operated by moving them with a cord, cane or control chain, or a motor, without touching the blinds directly.

Horizontal blinds are not designed to completely darken rooms. Light and sunlight can enter the room through gaps between the lamellae, holes in kitchen lamellae, between the edges of the blinds and the edge of the window, although the lamellae themselves are completely impervious to light.

The height of the manufactured aluminum blinds cannot be less than the ordered height. i.e. if the ordered height of the blinds does not match the repeating lamella spacing, the height of the finished blinds will exceed the ordered height by one lamella. Consequently, the finished blinds will always be higher than ordered blinds within a range of 0 to 14 mm (for a width of 16 mm) and up to 22 mm (for a width of 25 cm). This should be noted when ordering blinds. This additional height can be compensated for during use by raising the blinds slightly upwards.

The offered aluminum louvers are designed for medium intensity use. Over-intensive use causes accelerated wear and tear of the control elements - cords, bushings, gears, etc. - This is a natural wear and tear of the product and is not subject to warranty conditions.

Vertical blinds

Quality Indicators. Product properties

The dimensions of the product can vary within +/- 2 mm.

The shades of the components of the blinds may vary slightly from those of the samples shown.

Painted aluminum parts are considered to be of good quality if there are no flecks larger than 1 mm, if the distance between small flecks is greater than 10 mm, and their average number does not exceed 1 unit/dm2. Paint drips are not allowed, the presence of small single scratches on the surface of the paint is allowed. Any defects should not be visible to the naked eye from a distance of 3 meters at an angle of 60 degrees.

The lamellae of the blinds must not be touched by pushing or pulling, as this may cause damage to the lamellae themselves or their supporting structure. The louvres are operated by moving them with a cord, cane or control chain or motor, without touching the louvres directly.

Vertical blinds, except those made of fully opaque fabrics (TPO), are not intended to completely darken rooms. Light and sunlight can enter the room through gaps between the lamellae, at the top and bottom of the blinds, between the edges of the blinds and the edge of the window.

When fabrics with geometric patterns (stripes, squares, waves, etc.) are used to make blinds, the geometry of the pattern may not match the geometry of the product, i.e. the geometric shapes may not match the bottom, top or side edges of the product, the shape of the pattern on one lamella may not match the shape of the pattern on another lamella, which is not considered a defect.

The top profile of vertical blinds is installed straight, otherwise the lamellae may jam or the mechanism may not work properly.

Pleated blinds

Quality Indicators. Product properties

The folds of the blinds' fabric must not be touched by pushing or pulling, as this may cause damage to the lamellae themselves or their supporting structure. The blinds are operated by moving the upper or lower profile using the handles provided for this purpose.

Pleated blinds, except those made of fully opaque fabrics (PO), are not intended to completely darken rooms. Light and sunlight may enter the room through the gaps between the fabric and the fiberglass tape, at the top and bottom of the blinds, and through the holes in the fabric for attaching the cords.

When materials with geometric patterns (stripes, squares, waves, etc.) are used in products, the geometry of this pattern may not coincide with the geometry of the product, i.e. geometric figures may not coincide with the bottom, top or side edges of the product, fabric folds, which is not considered a defect.

Pleated blinds must not be pulled away from the glass (even with special handles), as this may damage (stretch) the springs holding the fabric. The blinds are operated by moving them parallel to the glass with the handle, while the top and bottom profiles must remain in a horizontal position.

The fabric of pleated blinds installed on roof windows must not be removed from the rails, as this can ruin the blinds.

The dimensions of the product can vary within +/- 2 mm.

Security shutters

Quality Indicators. Product properties

The dimensions of the product can vary within +/- 2 mm.

The shades of the components of the blinds may vary slightly from those of the samples shown.

The shades of the components of the blinds may vary slightly from one another.

Painted aluminum parts are considered to be of good quality if there are no flecks larger than 1 mm, if the distance between small flecks is greater than 10 mm, and their average number does not exceed 1 unit/dm2. Paint drips are not allowed, the presence of small single scratches on the surface of the paint is allowed. Any defects should not be visible to the naked eye from a distance of 3 meters at an angle of 60 degrees.

The safety shutters will not function if they are iced up. The louvers must be de-iced before they can be moved by motor or manual operation. Moving icy louvers can cause damage to the louvers.

Blinds must not be lifted directly by hand (except for spring-operated models with this type of control), nor must partially raised blinds be supported by foreign objects.

Security shutters function at their full capacity when they are fully deployed and all their blades are resting on each other.

awnings

The dimensions of the products can vary within +/-25 mm.

Wrinkles. Wrinkles can occur while cutting fabric, sewing, or attaching to an awning frame. A light-colored line may be visible at the site of the wrinkle, especially on light-colored fabrics. When viewed in the light, this line can be confused with a streak of dirt.

Wavy fabric. The fabric is twice as thick at the seams or at the edges. When the fabric is wound on the tube, the fabric is stretched with more force in these areas, which can cause a "wavy" effect.

Lengthening the edges of the fabric. The awning fabric is permanently in a taut position, whereby the seams and lining of the fabric provide additional reinforcement. When the fabric is rolled up, additional tension forces are generated at the seams and at the edges. This can result in wavy edges on the edges of the fabric.

"The honeycomb effect." To ensure optimum absorption of tension forces, vertical seams are made tighter than horizontal seams. The different weave of the seams can cause the so-called "waffle effect", which is intensified in damp or low-light conditions. To avoid this, try to avoid twisting damp fabric whenever possible.

In very rare cases, a "honeycomb effect" within the fabric may occur.

Fabric thickness. The fabric manufacturing process is subjected to high tension forces, which can cause thread breaks. In this case, the thickness of the fabric may vary in places, so that lighter areas or thread knots are visible under certain lighting conditions.

Facade blinds

Mismatch in the angle of rotation of the lamellae. When blinds are installed next to each other or when they are joined together by a common guide rail, the angle of rotation of the lamellae may not match. This mismatch can be up to 20 ⁰.

"The Arrow Effect. When lifting narrow and tall façade blinds, there is a possibility of a ladder between the lamellae, which may result in one edge being in a higher position relative to the other. This is most often the case for blinds with a width to height ratio of 1:4.

Deflection of the bottom profile. Wide blinds may have a slight deflection of the lower profile.

Tolerance with respect to boxes. Tolerance of bending and length of boxes - up to 5 mm.

Gates

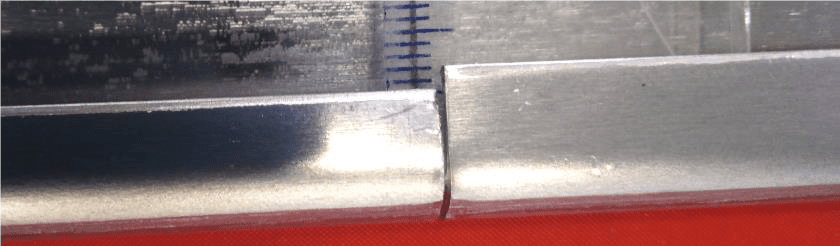

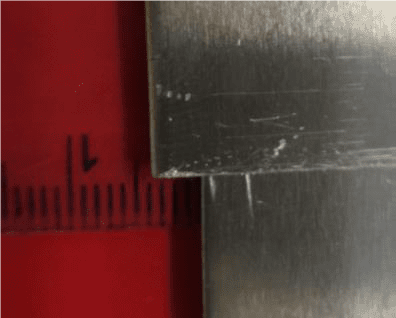

The length difference between the diagonal diagonals of the installed doors must not exceed 2 mm.

If there is a significant difference between the internal and external temperatures, the door segment may bend (due to expansion/contraction). The bending should not exceed 1/150 of the door width, if this value is exceeded, stop using the door immediately until the temperature difference is reduced.

Condensation is allowed to form on the inside of the window.

The gate is designed to function in conditions of relative humidity inside - up to 90%, outside - up to 100%.

Operating temperature of the door from -45 ⁰C to +40 ⁰C.

We are happy to answer all your questions by e-mail info@dexline.ee or by phone +37258438888